Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

The main project’s objective is to develop the production technology of components such as water turbine propellers, seawater pump elements (impellers, manifolds) and valves using newly developed Cubased alloys by means of 3DMP® technology, which is one of the most innovative technologies of the Wire Arc Additive Manufacturing (WAAM) processes. Importance of WAAM:

Within the framework of this project the parameters of the technological processes allowing to produce aforementioned components using wires made of Cu alloys as the input material will be optimized, using knowledge and expertise already available in the consortium. The technological solutions developed in this project will be novel in comparison with the current solutions based on the conventional metal processing technologies. Importantly, the new components printed with the Cu alloy wires can be reused after being melted and refined, which is consistent with the KIC 3 strategic goal, i.e. „closing material loops”.

Within the framework of this project the parameters of the technological processes allowing to produce aforementioned components using wires made of Cu alloys as the input material will be optimized, using knowledge and expertise already available in the consortium. The technological solutions developed in this project will be novel in comparison with the current solutions based on the conventional metal processing technologies. Importantly, the new components printed with the Cu alloy wires can be reused after being melted and refined, which is consistent with the KIC 3 strategic goal, i.e. „closing material loops”.

The production technologies proposed within this project can use scrap as a material for the production of the wires and do not generate wastes. The main advantages of the solution is using wires as the input material instead of metal powders, which is way more suitable to generate low to medium complexity and medium to large scale components. Presently, in the WAAM processes, mainly wires made of steel, aluminium and titanium are used. This project is aimed at developing new wires made of Cu based alloys. The scope of work of this project covers all crucial stages for application of the new Cu based wires in the 3DMP® production process at the industrial scale. The project envisages also the influence of the 3DMP® process on the resulting mechanical properties of the Cu based alloys. Thus, realization of the planned research will contribute to extending the knowledge concerning the chemical compositions of the Cubased alloys intended to be used in the additive manufacturing processes. This will expand the impact of this project, because that knowledge together with new technology can be used in the development of other products for different applications.

The developed technology will give Gefertec GmbH advantage over competitors and is one of the most important strategic aspects of the project. The seawater environment is very destructive for metal materials, so the knowledge and technological possibilities to develop new products which will be corrosion and wear resistant and can operate for a long period of time in such condition are crucial to be successful in this field. One should also take notice of material consumption during production. BuytoFly (BTF) ratio for the traditionally manufactured parts (casting, plastic working, machining) is most of the time around 1020 and sometimes even above 30. For 3DMP® BTF ratio is usually around 1.5, but never above 2.0. Shortening lead times and significant material saving are additional key strategic effects of the project. Another strong advantage of 3DMP® is the fact that it can be used for maintenance and repair operations. It is easily possible to take an existing part that ends up being broken and use software to scan it and then rebuild the product. During traditional manufacturing, shrinkage cavities, oxide notches and other defects can occur often in the product which can lead to long and expensive repairs or rejects. An alternative to this technology is WAAM, which consists of the fabrication of parts layer by layer with a wire fusion by automatic arc welding. The achievement of the project’s objectives enable to implement new manufacturing technology for corrosion resistant components that will be made of new grades of Cu based alloys. The technology of propellers production is connected with the production devices which can be also offered to the customers interested in technologies of renewable energy production and marine industry. This will enable to Gefertec GmbH to introduce the new product to the offer which increase the innovativeness and competitiveness of the enterprise. The technology readiness level TRL will reach 9 after the project. The technological processes developed within the project will be ready to implement. The planned research program is focused on the work necessary to start the industrial production of the marine propellers and other marine equipment intended for the power stations which recover the energy from the sea tides and also for ship industry. We hence believe this 3DMPWire project is of strategic importance for strengthening the European position in the emerging field of 3D printing for challenging and material-intensive environments, such as the marine sector.

The developed technology will give Gefertec GmbH advantage over competitors and is one of the most important strategic aspects of the project. The seawater environment is very destructive for metal materials, so the knowledge and technological possibilities to develop new products which will be corrosion and wear resistant and can operate for a long period of time in such condition are crucial to be successful in this field. One should also take notice of material consumption during production. BuytoFly (BTF) ratio for the traditionally manufactured parts (casting, plastic working, machining) is most of the time around 1020 and sometimes even above 30. For 3DMP® BTF ratio is usually around 1.5, but never above 2.0. Shortening lead times and significant material saving are additional key strategic effects of the project. Another strong advantage of 3DMP® is the fact that it can be used for maintenance and repair operations. It is easily possible to take an existing part that ends up being broken and use software to scan it and then rebuild the product. During traditional manufacturing, shrinkage cavities, oxide notches and other defects can occur often in the product which can lead to long and expensive repairs or rejects. An alternative to this technology is WAAM, which consists of the fabrication of parts layer by layer with a wire fusion by automatic arc welding. The achievement of the project’s objectives enable to implement new manufacturing technology for corrosion resistant components that will be made of new grades of Cu based alloys. The technology of propellers production is connected with the production devices which can be also offered to the customers interested in technologies of renewable energy production and marine industry. This will enable to Gefertec GmbH to introduce the new product to the offer which increase the innovativeness and competitiveness of the enterprise. The technology readiness level TRL will reach 9 after the project. The technological processes developed within the project will be ready to implement. The planned research program is focused on the work necessary to start the industrial production of the marine propellers and other marine equipment intended for the power stations which recover the energy from the sea tides and also for ship industry. We hence believe this 3DMPWire project is of strategic importance for strengthening the European position in the emerging field of 3D printing for challenging and material-intensive environments, such as the marine sector.

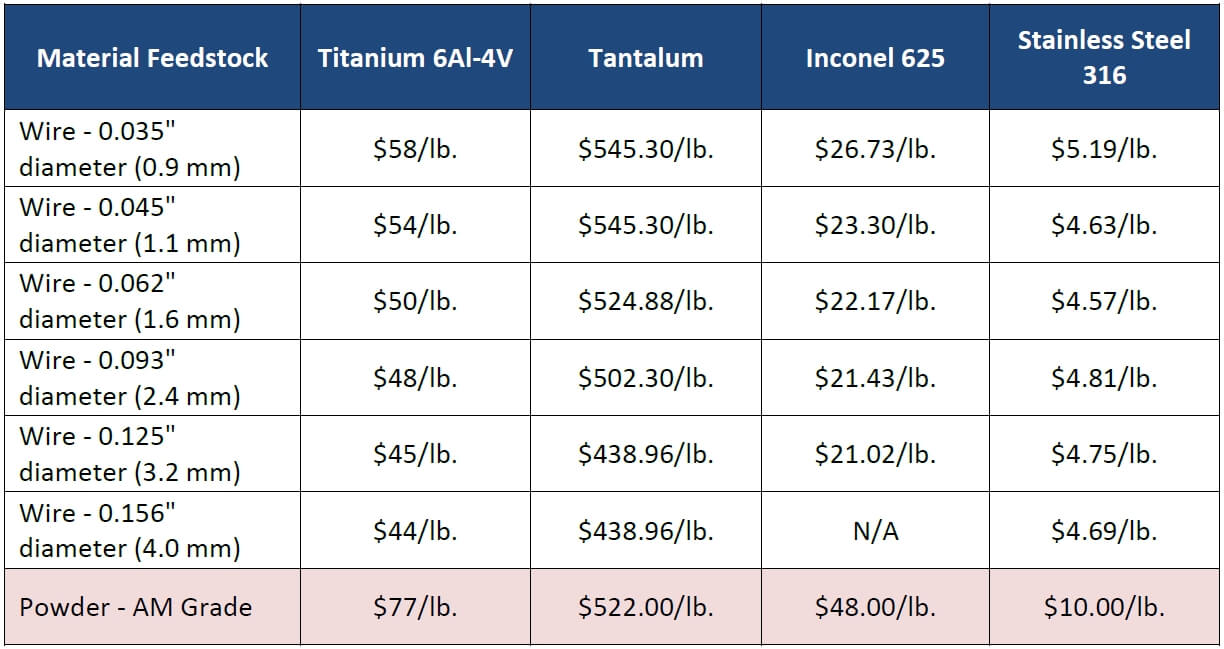

Table 1. Cost comparison between wire and powder feedstock for various materials.

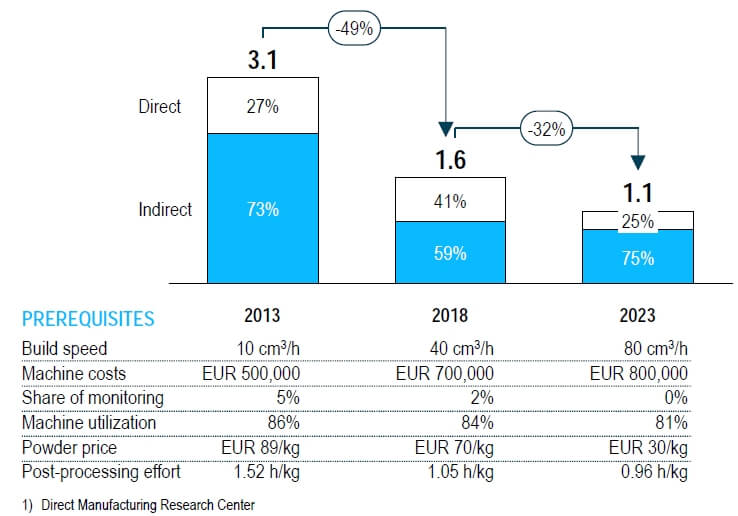

Fig. 1. Cost evolution requirements in order to reach a profitable business case for additive manufacturing (powder bed).

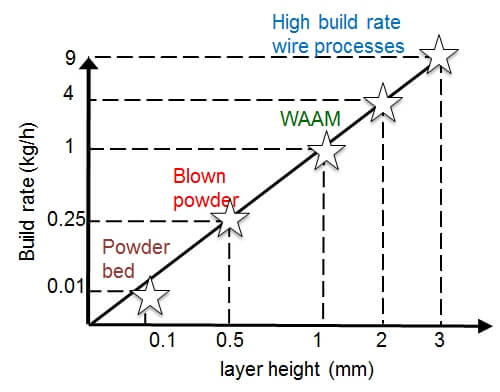

Fig. 2. Deposition rates for various additive manufacturing technologies.

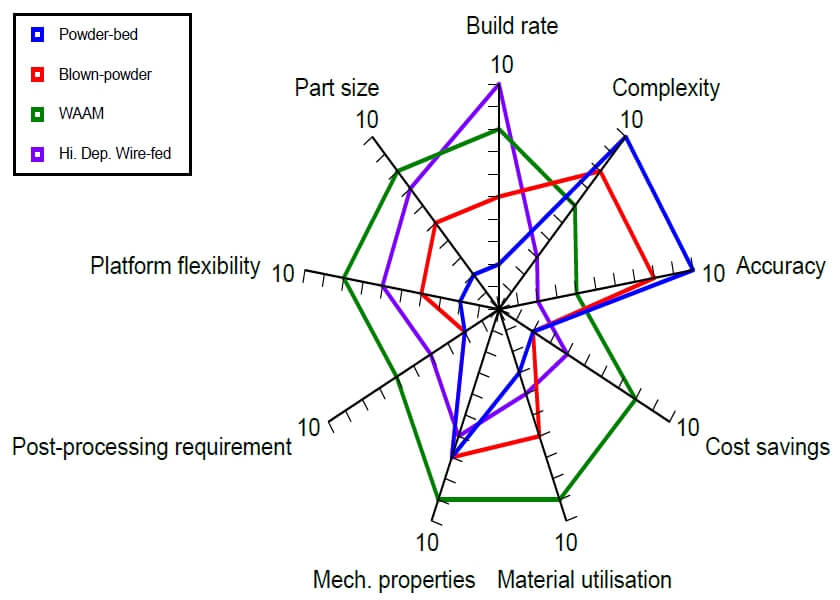

Fig. 3. Global comparison of different additive manufacturing technologies.