Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

Material-efficient Cu wire-based 3D printing technology

Area Acceleration (D2) Segment Upscaling (D2.2) Duration 2019/01/01-2021/12/31

The project focuses on one of the priority sectors of application of raw materials, i.e. energy. The projects addressing advanced manufacturing technologies are considered a part of the Key Enabling Technologies for the European industry. There is a need to strengthen the manufacturing segment of the value chain in Europe and one of the main objectives of the project is to address that challenge in an appropriate way by implementation of innovative production methods in industrial practice.

The project focuses on one of the priority sectors of application of raw materials, i.e. energy. The projects addressing advanced manufacturing technologies are considered a part of the Key Enabling Technologies for the European industry. There is a need to strengthen the manufacturing segment of the value chain in Europe and one of the main objectives of the project is to address that challenge in an appropriate way by implementation of innovative production methods in industrial practice.

The 3DMPWire project will have direct impact, as the resulting development will be directly used by one of the consortium partners who is ready to make an investment decision for new production units as necessary for industrialscale production. Successful launching of the production technology will bring material savings in production process on the one hand while on the other hand it will reduce its environmental footprint. Integration of educational activities in the scope of the project will help to overcome already identified barriers to additive manufacturing deployment, such as lack of skill and knowledge as well as lack of awareness among potential user communities.

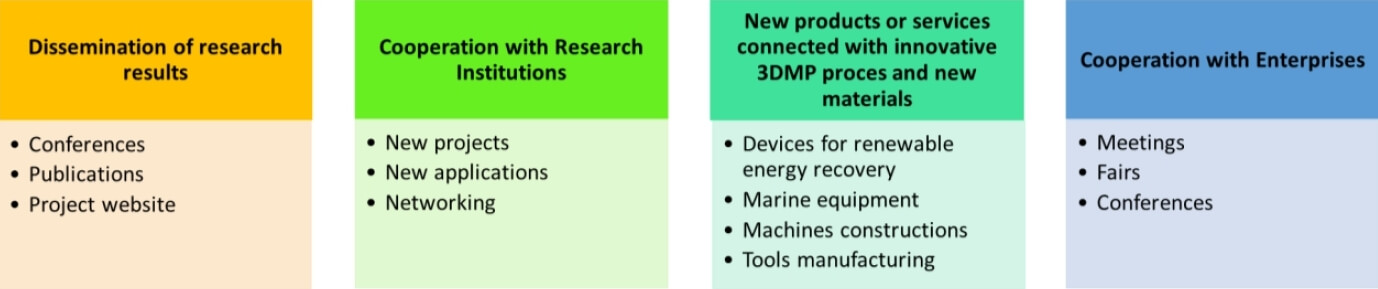

Demonstration of project results within the EIT Raw Materials community will open opportunities for crossregional and crossvalue chain collaboration and will be seen as a potential starting point for establishing cooperation and knowledge sharing between other additive manufacturing related KIC projects. The diagram which depicts the impact and benefits of this project is presented in Fig. 1.

Fig. 1. Areas of impact and benefits.

Fig. 1. Areas of impact and benefits.